The Firewire Surfboard Constructions

Getting to know Firewire's Surfboard Constructions

Although Firewire is now a household name in the surfboard world, many people on our side of the Pacific don’t realize that it actually has a deep and rich history that dates back to the 1990s. Firewire was actually originally the surfboard brand Nev, which was headed up by Neville Hyman, a respected and prolific shaper in Western Australia.

Hyman expanded Nev and created Firewire in 2006, using machine shaping technology and epoxy sandwich construction to create some of the most high-tech surfboards on the market. Since that time, virtually every respected board company has gone on to adopt some sort of variation on Firewire’s futuristic construction processes. In the meantime, Firewire has expanded globally, acquiring a number of other brands (including Carve Sport’s Thunderbolt longboard line, with names such as Harley Ingleby, Kai Sallas, CJ Nelson, Ben “Skindog” Skinner, and Taylor Jensen) and adding a number of the world’s best surfboards designers and shapers to their stable.

Kelly Slater invested in the company a few years back and integrated his Slater Designs boards into the Firewire family, bringing shapers such as Dan Mann, Akila Aipa, and Daniel “Tomo” Thomson to the team. And Rob Machado has recently come on as a surfboard designer/shaper, adding his cruisey aesthetic to the quiver.

Hyman expanded Nev and created Firewire in 2006, using machine shaping technology and epoxy sandwich construction to create some of the most high-tech surfboards on the market. Since that time, virtually every respected board company has gone on to adopt some sort of variation on Firewire’s futuristic construction processes. In the meantime, Firewire has expanded globally, acquiring a number of other brands (including Carve Sport’s Thunderbolt longboard line, with names such as Harley Ingleby, Kai Sallas, CJ Nelson, Ben “Skindog” Skinner, and Taylor Jensen) and adding a number of the world’s best surfboards designers and shapers to their stable.

Kelly Slater invested in the company a few years back and integrated his Slater Designs boards into the Firewire family, bringing shapers such as Dan Mann, Akila Aipa, and Daniel “Tomo” Thomson to the team. And Rob Machado has recently come on as a surfboard designer/shaper, adding his cruisey aesthetic to the quiver.

FIREWIRE'S COMMITMENT TO INNOVATION AND SUSTAINABILITY

From the materials they source to the techniques they use to manufacture, Firewire has one simple goal: to ensure the best performing surfboards leave the smallest environmental footprint possible. Their dedication shows in their innovative design, new materials, and advanced construction methods.

CURRENT CONSTRUCTION TECHNOLOGIES

Firewire currently runs with three different technologies, with some recent significant changes:

The Helium Technology

Deck skins make a difference and Helium's deck skin is exceptional. When you load up turns or push hard off the bottom you'll feel your feet sinking into the deck as we all enjoy when creating footwells, but Helium's deck skin has a memory that rebounds back to form after being compressed. It often looks pristine after removing wax following your first several surfs. Aerospace composites applied to surfing at their finest.

The Helium technology features parabolic rails made with a blend of paulownia and balsa wood. This construction allows for a specific type of torsional flex, similar to how a snowboard twists and pops, then unloads. The design provides a lively feel in the water and performs particularly well when you need to generate speed in weaker waves.

The Seaside built in Helium Tech – an ultralight EPS foam core with flex controlled in the rail from nose to tail; a blend of paulownia and balsa wood. Aerospace composite deckskins make you feel like you’re creating footwells in the deck, but it often looks new even after a month of surfing.

Ridden by everyone from Kellly Slater and Stuey Kennedy and Pacha Light. It’s our lightest surfboard ever, shaped from a 0.8 pound EPS blank with flex controlled at the rails similar to Timbertek.

The Ibolic Technology

Firewire has spent the past year innovating newer, better construction processes for its wide range of boards—which is pretty impressive, since it already led the industry in futuristic tech. The latest option is the Ibolic Construction, which replaces the LFT construction.

Key features include:

Ibolic was designed around the fact that many of Firewire’s more futuristic shapes had pretty complex bottom contours, particularly the vee quad concave bottom used on many of Tomo’s boards. This “performance hull” contour is quite involved and is difficult to glass with a bottom skin, which was the typical process used for the LFT boards.

With an 'I-Beam' high density foam stringer (hence the name) and high density parabolic rails, Ibolic has the strength and stiffness of LFT coupled with the flex and spring back of Helium. Over the course of the development process of this new technology, the involvement and feedback from Kelly and the team has been invaluable. Many hours were spent testing in all conditions and the 'go-to' models were the FRK, REVO and the Sci-Fi 2.0 Launching with the debut of Ibolic, we are featuring select sizes in the models that showcase the tech's attributes particularly well.

The Volcanic Technology

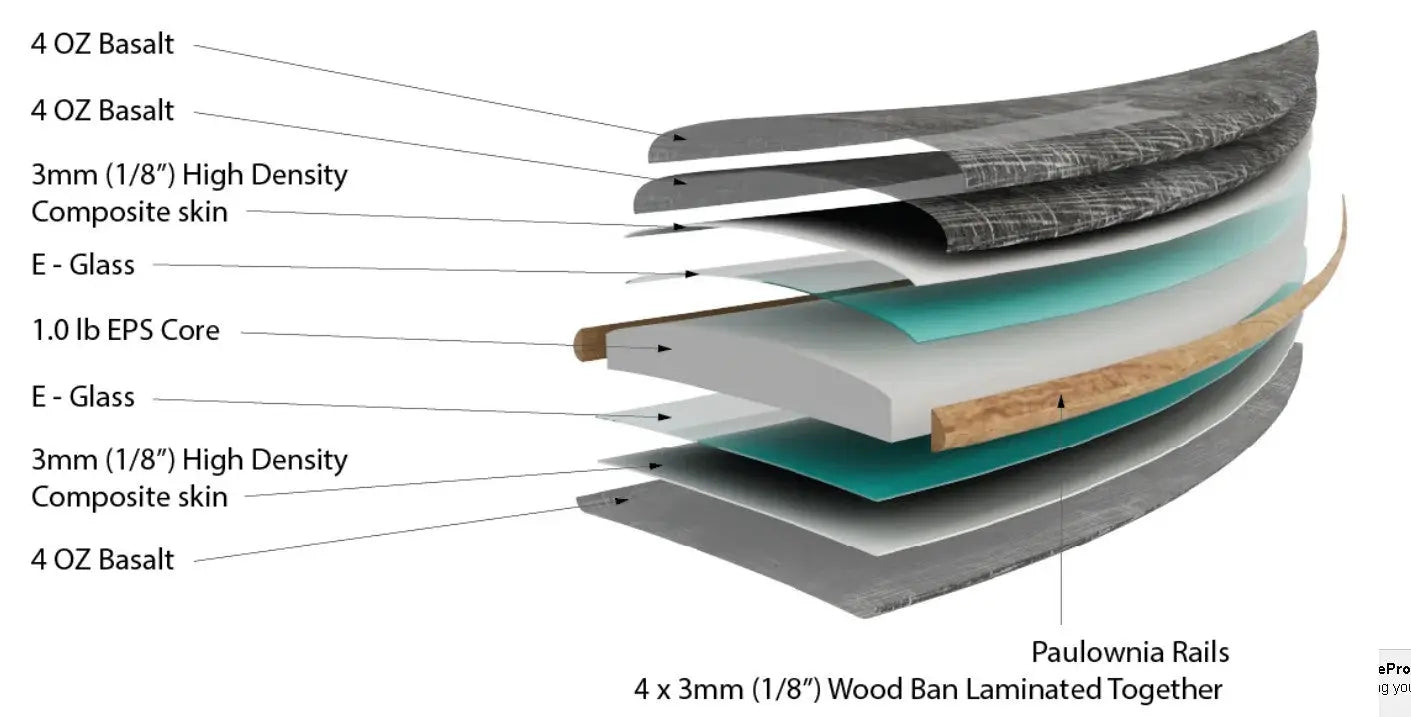

An important clarification from Firewire: Volcanic is not a separate construction technology but rather a specialized lamination schedule or glass job. This process uses basalt cloth instead of traditional fiberglass in the lamination process. Basalt cloth is made from volcanic rock extruded at extremely high temperatures and woven into a material similar to fiberglass and carbon fiber.

Coming from an island that was created by a volcano, it seems natural to ride boards created by the same forces. We are excited to start testing the Volcanic Tech on Hawaii’s reefs!

Coming from an island that was created by a volcano, it seems natural to ride boards created by the same forces. We are excited to start testing the Volcanic Tech on Hawaii’s reefs!

The Timbertek Technology

When most people think of Firewire, they think of TIMBERTEK. These are the brown, wooden-decked surfboards that first put the company on the map. Combining lightweight EPS blanks with laminated wooden skin and proprietary parabolic rails, these boards look good and perform great. They are strong, lightweight, and snappy, utilizing the strength of paulownia wood to supplement the strength and flex of the EPS foam and epoxy resin.

The Timbertek surfboards are just as impressive for their performance. The parabolic rail construction eliminates the need for a center stringer, and instead moves the boards’ flex and life to the rails, where more torque and movement occurs. The result is a hyper-sensitive and maneuverable board that is stronger while at the same time being lighter—the holy grail of surfboard technology. The fact that it’s beautiful is just icing on the cake!

THE LFT OR LINEAR FLEX TECHNOLOGY

The deck of every LFT surfboard is crafted to nest slowly beneath your feet, creating familiar foot places on the deck beneath your heel, arch, and toes, for comfort without the cracks, snaps or shatters associated with PU / Poly boards over time. "It feels like home," says Rob Machado, "when you hit the magic spot your heel sits in it and locks in."

He continues to explain that “Helium is light and lively, and great for generating speed in weak waves. LFT is still light, but a little more drivey and solid, and great for controlling speed in better waves.”

LFT incorporates Firewire’s SPRINGER HD, a 0.75” (18 mm) wide aerospace composite that runs down the centerline of the board, representing the next generation in our SPRINGER technology. The SPRINGER HD runs the entire length of the board and plays a pivotal role in optimizing flex from nose to tail.